Embedded with Xilinx FPGA, programming by VisualApllet to realize a disruptive embedded machine vision system

Breeze clouds FPGA development circles

as early as 2014, the world's leading Xilinx's All Programmable technologies and devices together eco-partner Germany Silicon Software Silicon Software has introduced the company's VisualApplet software platform. This software platform implements a graphical FPGA design and programming environment for Xilinx Zynq-7000 All Programmable SoC. Since then, this platform has almost overturned the traditional embedded machine vision system, bringing an unprecedented embedded design experience for embedded system architects, software engineers, and hardware engineers who are engaged in and looking for advanced, high-performance machine vision solutions.

Visual Applet is a graphical development tool. It can simplify complex FPGA programming with simple drag and drop. Silicon Software provides a series of image preprocessing Applets. By combining these Applets, users can customize their own images. Preprocessing function. In addition, these Applets will be loaded into the MicroEnable series of frame grabbers when they run without taking up system CPU resources. They are a hardware-based platform for image preprocessing software. Moreover, all functional modules are provided in the form of hardware operators, which guarantees the requirements of real-time processing. Therefore, the complexity of graphics processing is only limited to the resources of the FPGA used.

When using Visaul Applet for image processing algorithm development, there is no need to consider synchronization, timing, and other optimization issues that are often considered in FPGA design. FPGA synthesis and advanced simulation can be completed in half an hour, which greatly simplifies the difficulty of real-time image processing design.

LX VisualApplet industrial camera:

Baumer's latest smart device LX VisualApplet industrial camera, due to its unique image solution, can achieve a high frame rate of 20M pixels during image and video transmission. This is mainly due to the fact that this camera not only uses FPGA for full acceleration, but also performs different image preprocessing in real time according to the special purpose of different applications when programming applications in the VisualApplets chart programming environment based on silicon software. , And this pre-processing process not only increases the output of the image system, but also can respond in real time when the amount of data uploaded to the host is reduced (lost).

Figure Baumer intelligent LX VisualApplets industrial camera

What is curious is how does this camera preprocess images? It turns out that when Baumer's LX VisualApplet camera performs preprocessing, it will use the Xilinx Spartan-6 LX150 FPGA and 256MB DDR3 SDRAM inside the camera. It is the support of these two parts that realizes the image Pretreatment. In addition, this camera also supports the GigE Vision interface standard (100m cable) [GigE Vision GigE Vision Standard is a set of high-performance industrial camera interface standards announced in 2006], coincidentally, in 2016 the most recent vision system design innovation award In, this new type of industrial camera won the Platinum Award.

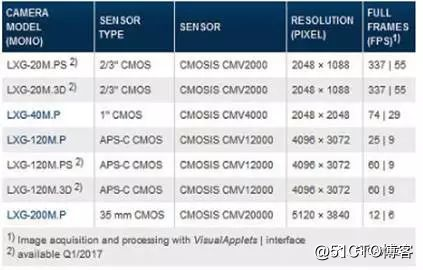

In Baumer's LX VisualApplets industrial camera product system, due to different sensor solutions, the transmission rate is divided into seven modes from 2Mbyte pixels to 200MByte pixels. Of course, this camera is implemented using CMOSIS image sensors. The following table lists the seven modes of this camera series from 2D to 3D:

to sum up:

Nowadays, a large number of smart industrial cameras are used in the fields of cutting-edge industrial automation and robotics. At the same time, more flexible and scalable solutions are required. This requires the transfer of real-time video processing functions from the local host or server to the camera. At the end, Xilinx Spartan-6 LX150 FPGA is built with 45nm technology, which can be easily embedded in the camera and provides video analysis functions, while also supporting image/video processing and sensor functions.