This scenario describes the hardware based on staged development process as well as in Leangoo project management software how implementation.

Hardware product development process

The figure below shows a hardware product development is generally subjected to all the processes needed:

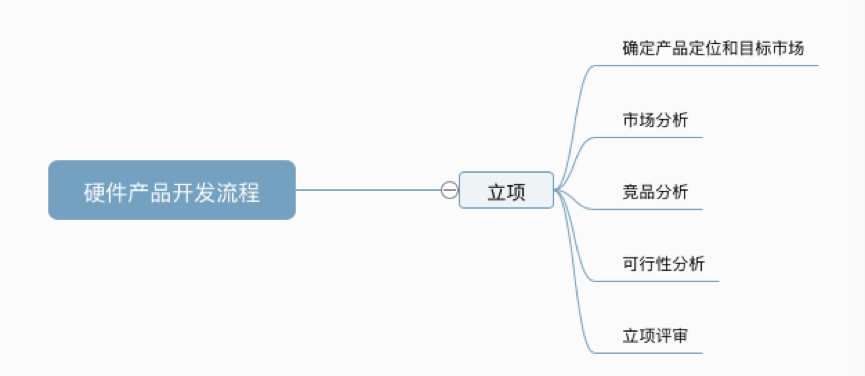

1) project

First need to determine product positioning before the project, market size, user needs, strengths and weaknesses of competing products, and other aspects for analysis. By comprehensive analysis if feasible, if feasible, then enter the project review stage, after review by can enter the start-up phase.

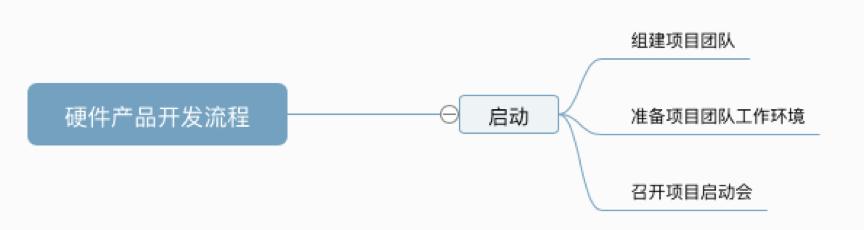

2) Start

In the start-up phase, we need to set up a project team to determine the personnel involved in product, communication is a function of the product manager, how will all the participants to work with a collection, how to communicate more effectively, to define their respective responsibilities and are ready for the project team office space and equipment.

After the above is complete, the project will be officially launched.

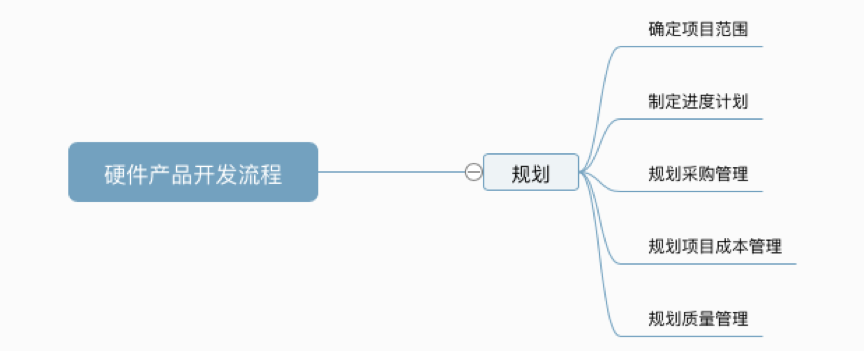

3) Plan

After completion of the formation of the team, entered the planning stage. This stage will need to be determined for product demand and refining the core functionality.

The development schedule, schedule time each node release from project start to project the entire process and each stage.

Planning and procurement management, project cost management plan, quality management, product quality metrics such as the definition of

4) Design

After planning to do, we enter the design phase, the design phase of the ID design, such as the ID Evaluation and Assessment are OK you can enter the structure design, electronic design (including PCBA design, electronics selection, determine the PCB, etc.), software design and development ( including software prototyping, for software development and the like), the whole verification (structural, electronic, software, etc. binding verification)

After determining the basic appearance, functionality, configuration, design into the packaging (a package insert, proofing materials, effects, etc.).

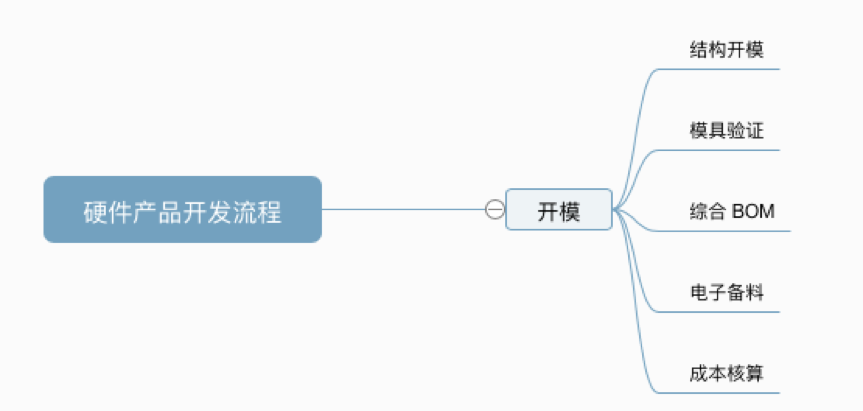

5) mold

After several tests in the product, if in the case of ID, configuration, there is no need to change the design of the electronic mold a mold opening start. In the mold of time, we need to regularly check the progress and quality of the mold to avoid a larger schedule delays or mistakes. Mold comprises a mold structure, a mold verification, the BOM integrated, electronic preparation, cost accounting.

6) Pilot

After the mold opening phase, trial production can be carried out in accordance with the situation, so that a comprehensive test machine.

Pilot structural member comprising, electronics, packaging materials, assembling a plurality of authentication, etc.

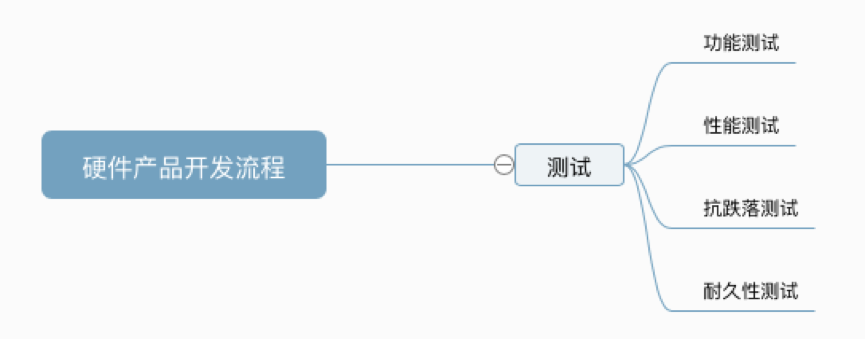

7) Test

This step is very important test, although the test will be carried out thorough prohibited before, but still can not guarantee to cover a variety of scenarios practical applications.

Test including functional testing, performance testing, durability testing

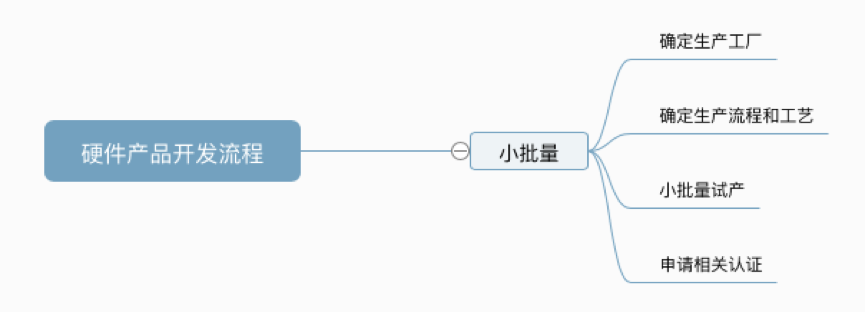

8) small quantities

After After a trial production and test, fix the problems found, can be a small batch production, we first need to determine small batch production plants, production processes and technology.

Then we can begin the product certification application in all aspects.

If small batch no problem, then you can enter the next step of the mass production.

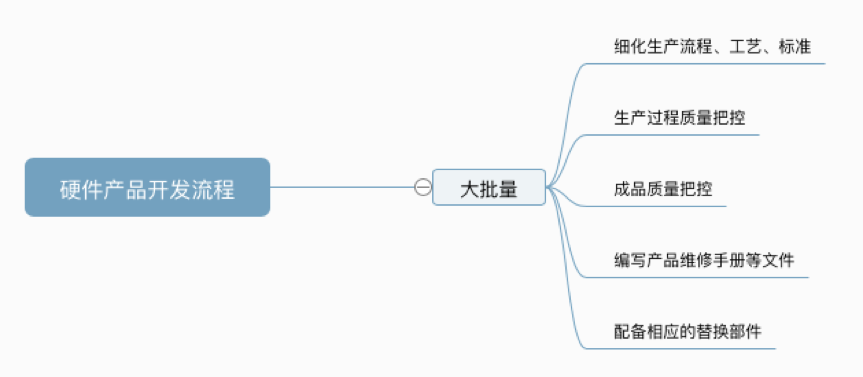

9) in large quantities

In mass production, the need for terms of technology, operating standards and the degree of product quality inspection specifications and ensure effective supervision. In the production process of product managers need to start writing product maintenance manuals, prepare the appropriate maintenance and replacement of parts, to prepare for sale and use.

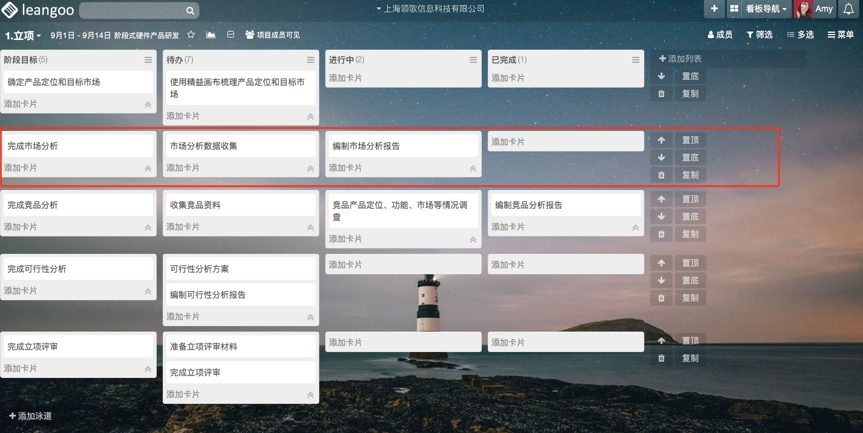

How to use Leangoo project management software to support hardware-stage product development

First we Leangoo, create a project (project selection phase type)

In the staged project, it is recommended to use leangoo in "staged and hardware product development" project template.

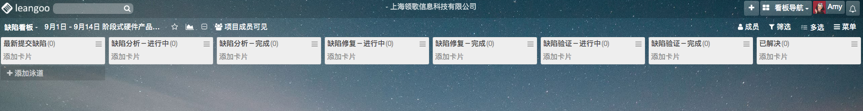

In the "hardware-stage product development" project template, the system automatically creates a nine stages and a defect billboards billboards for you, defect tracking management Kanban for product defects.

As shown below:

At each stage kanban, the reference samples are provided to the phase of the target needs to be done, by reference ~

1) staged Kanban

A standard phase billboards include: milestones, to-do, in progress, completed, as shown below:

- Milestones: placing a target at this stage need to reach each target a card account for a lane.

- To Do: Put in order to complete specific tasks (work items) milestones needs to be done, a target corresponding to a plurality of tasks. (Red box as shown above)

- In progress: ongoing task.

- Completion: completed tasks.

2) defects Kanban

For managing product defect tracking system has set a good flow of defect treatment for you. (You may need to customize the process)

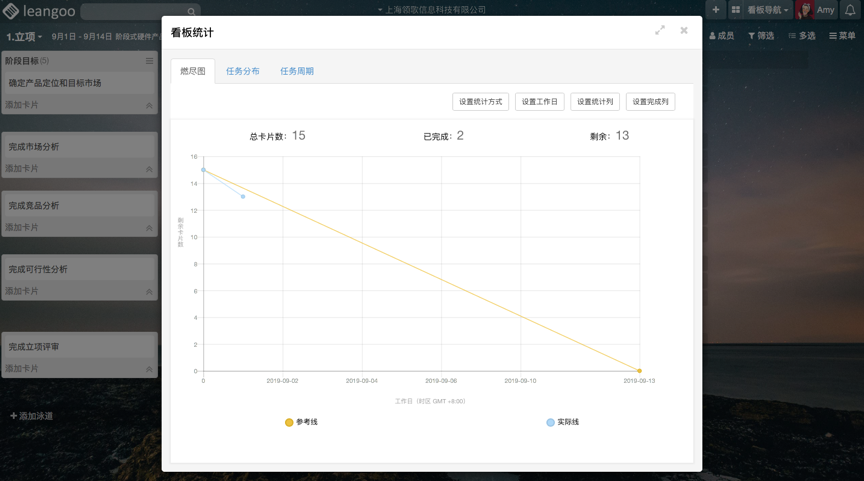

Tracking the progress of each stage

Tracking the overall progress of the project

Note: For different companies, different products may have different procedures and requirements. Above can be used as a reference -

Leangoo official website: www.leangoo.com