Transfer: https: //www.leangoo.com/10464.html

Defect management often focus on the following aspects:

1. defect processing speed

2. The process of defect state

3. distribution of defects

4. Reasons defects generated

using Leangoo Kanban We can visualize the defect management, to help us deal with the progress of the defect, the person in charge, all aspects of the current state of the distribution at a glance. Let's learn how to use Leangoo management deficiencies.

1. informed of the progress and status of defects

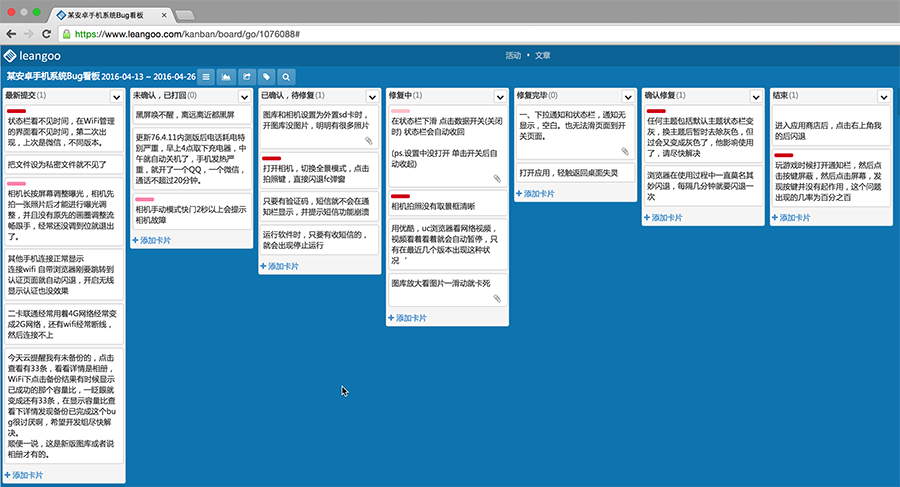

In leangoo, we can create one or more product defect management for a project or billboards. On billboards, we use the listing status on behalf of the defect, the list of card represents a defect.

Shown in Figure 1, we put into the state of the defect: the latest commit, unconfirmed fight back, has been confirmed to be repaired, the repair, the repair is completed, confirm the restoration, the end, a total of seven states, created a state for each list. We can progress defect treatment of the defect and drag it to a different list. In each state the title bar of the list we also state the number of defects in the statistics, not only so that we can know the current state of the defect, can also be very clear that the number of defects in each state, in order to analyze whether the workflow in our bottlenecks, help us optimize improve efficiency.

figure 1

2. The designated person responsible for defects

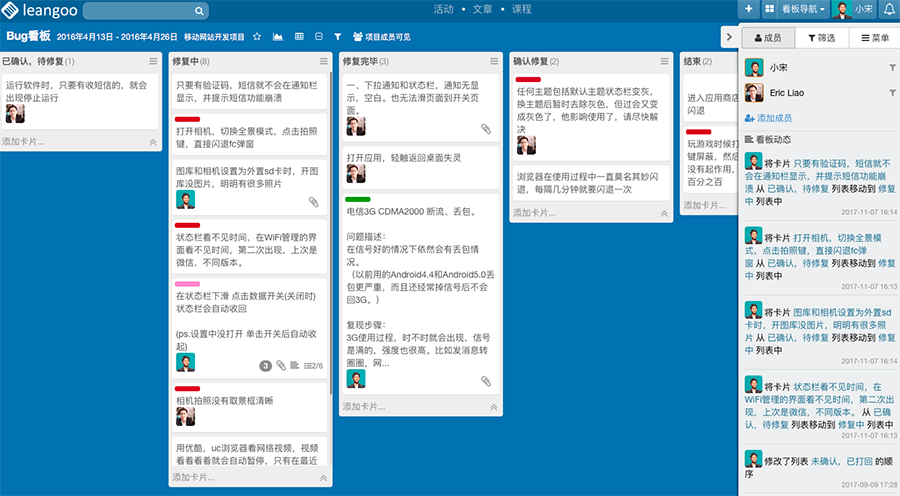

For each defective card, we can drag Kanban Kanban members of the right side of the designated person responsible for the card on the card. as shown in picture 2:

figure 2

You can also open a card, click on the "members" can also set the person in charge of the defect, as shown in Fig.

image 3

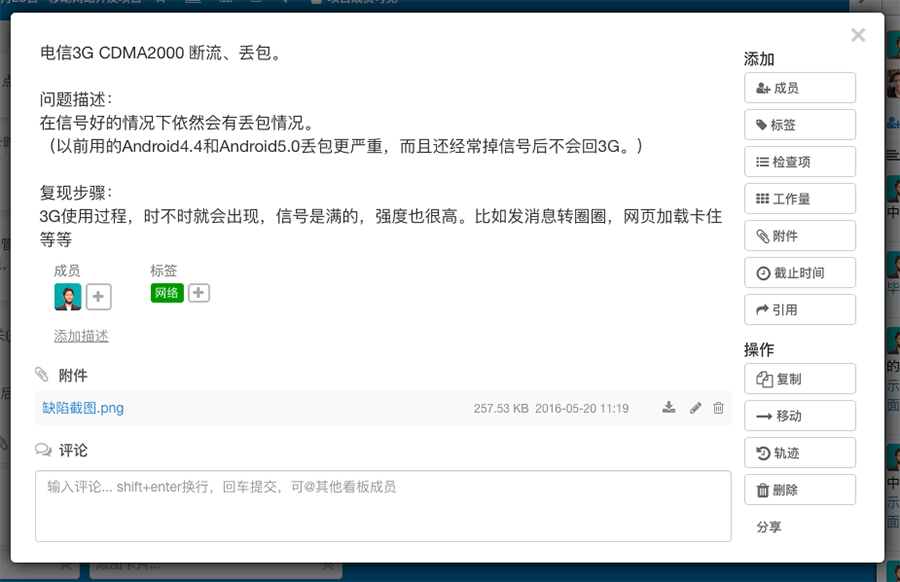

3. Edit the defect content

Compare came from a defect content, click on the list below to add the card to edit it. If the defect more content, easier to edit, you can open the card, the card edit panel, as shown in FIG. 140 words before the card content will be displayed on the card kanban, opening the card to see all the details.

If the defect related screenshots, can be added by clicking on the right side of the attachment button to upload screenshots defects, or add an attachment link.

Figure 4

4. defect classification and filtering statistics

1) are classified by different Kanban

If the product or project a larger scale, different modules or subsystems by different teams, you can build a team for each defect billboards. In addition, it is possible to set the Kanban cycle, such as a monthly period, regular analysis of the causes and distribution of defects, defect handling and team speed.

2) classified by label

In leangoo which, for each card we can customize the tag, which may be a level of defects, defect type, or may be a module. Selection tab filtered on a kanban can look at the statistics and the number of cards label.

Summary, Leangoo is a free, simple and practical tool for Kanban, Kanban visual defect management is not only convenient, but also help us to identify problems and bottlenecks, and optimize the efficiency of the team.