In the advanced technology, foundry cut metal used to achieve a smaller end-of-line spacing, and cut metal technology is accompanied by the metal extension. Today, little sister, I hope we can learn under the cut metal and metal extension together and share some experiences debug related issues.

As shown, the cut metal using the technology (the complete disconnection of the metal shape as separate etching Shape), can achieve a smaller end-of-linespacing.

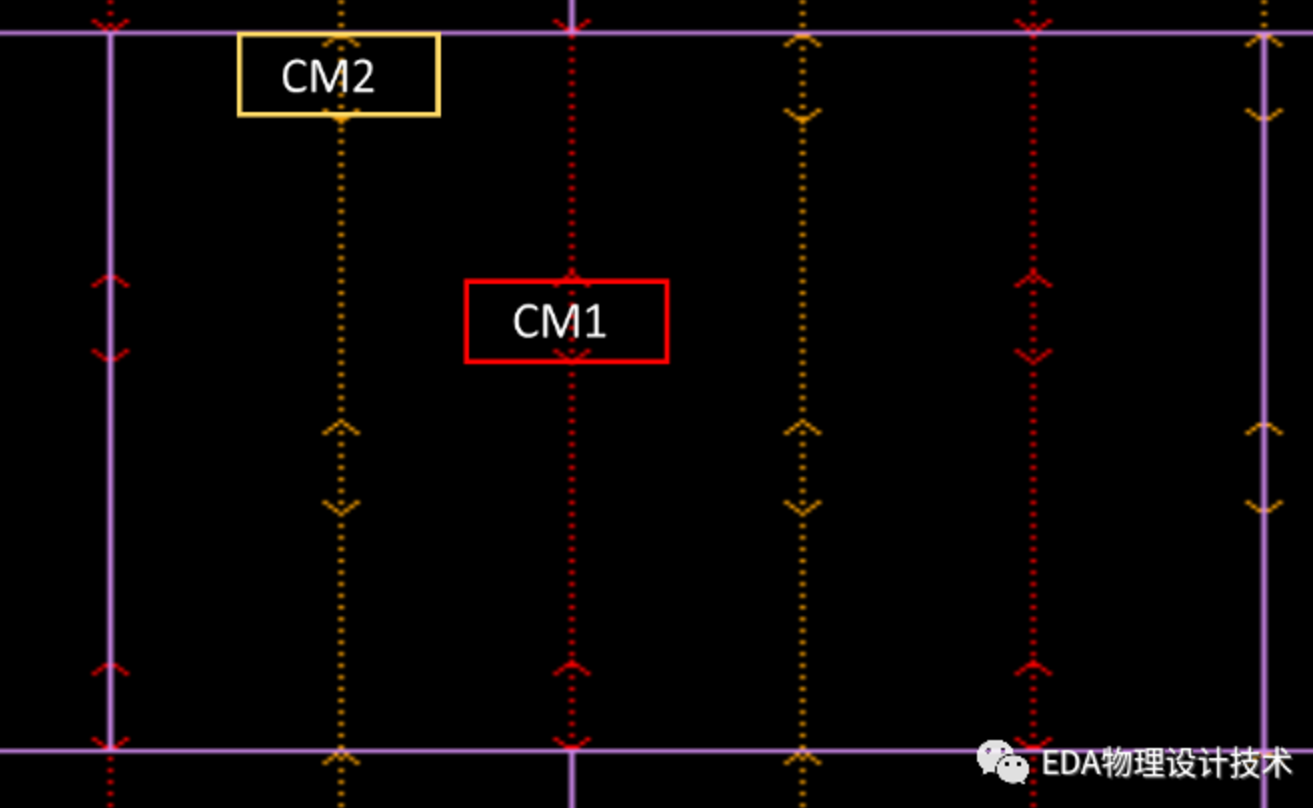

ICC2 cut metal support from P & R art to achieve the signoff. Layer cut metal 1 is usually only be inserted in a fixed position (preferred grid), Layer 2cut metal no fixed positions (refer to the corresponding specific process). The figure below shows a good track to create Layer1 arrows (preferred grid) on the track shows local cut metal that may be present. Therefore, we first need the right to create a good track.

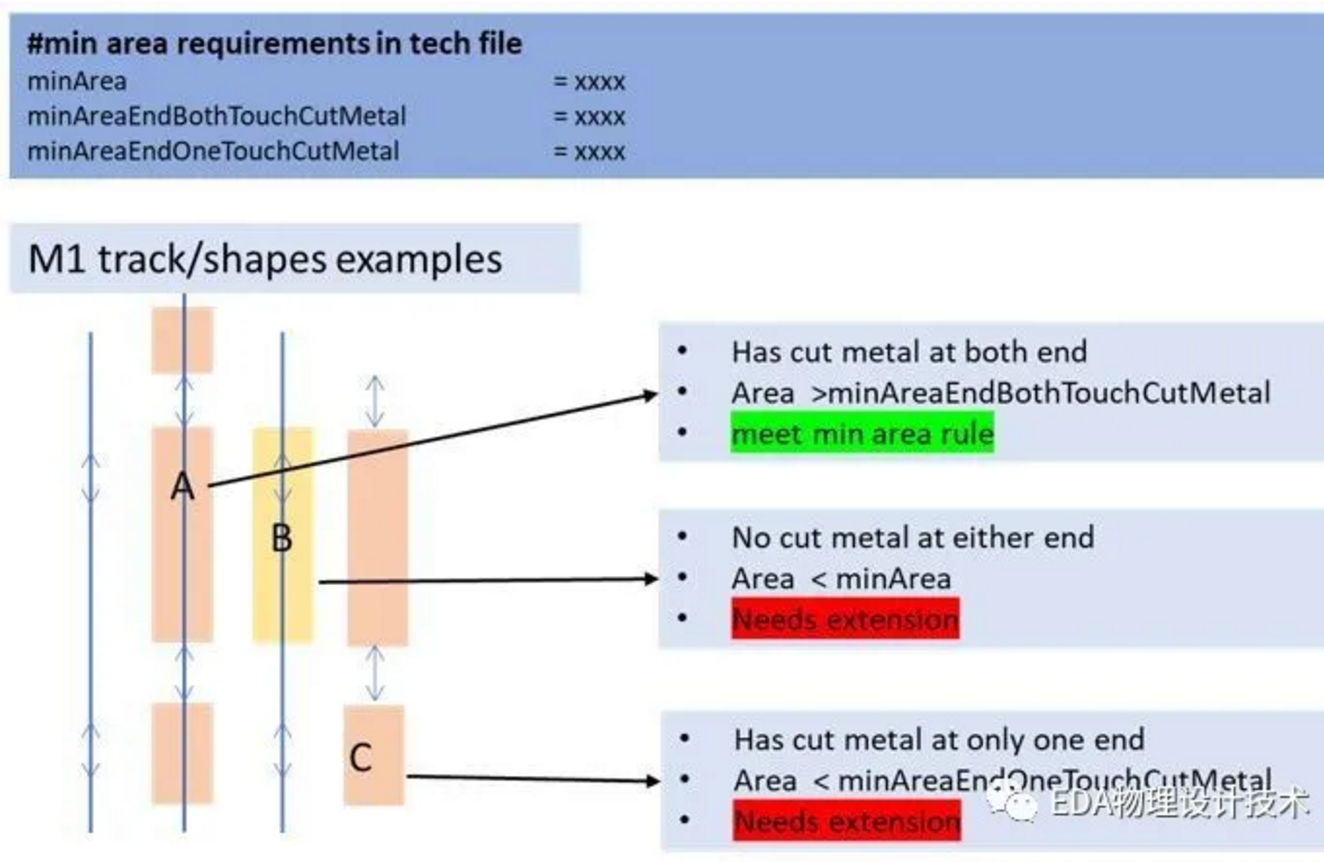

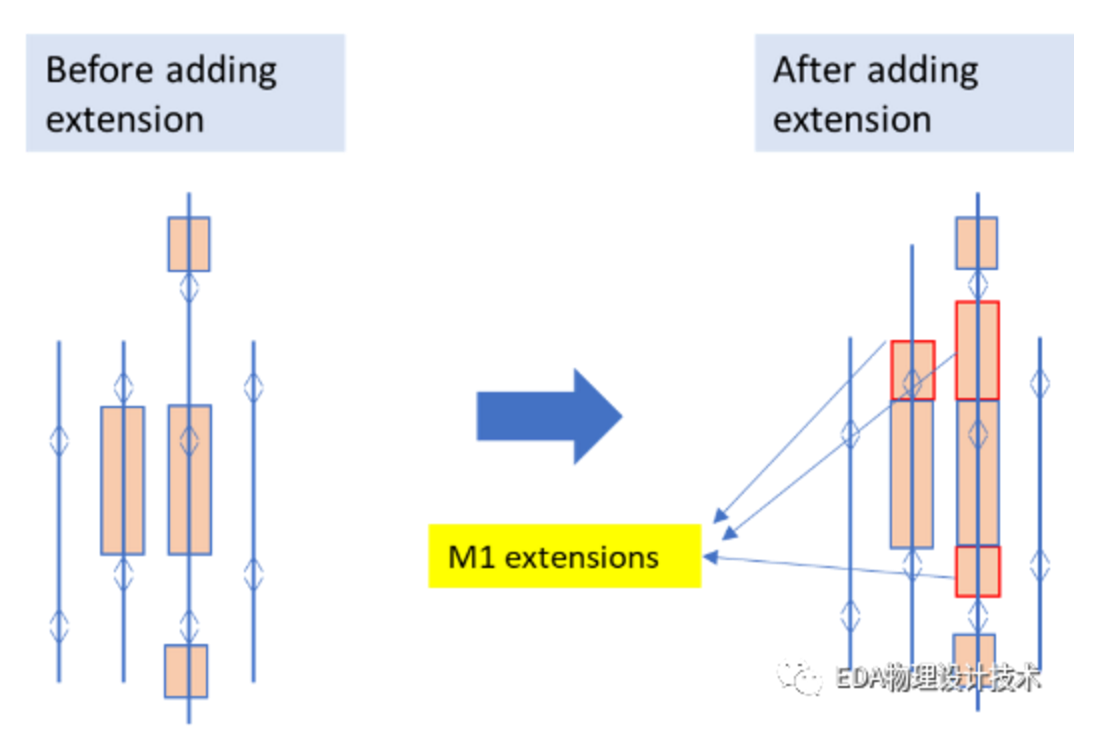

In advanced technology, there is usually minArea requirements for M1 Pin shape or metal shape. When minArea does not meet the requirements, we need metal extension, to meet the requirements minArea. The following figure shows the shape of the required metal extension.

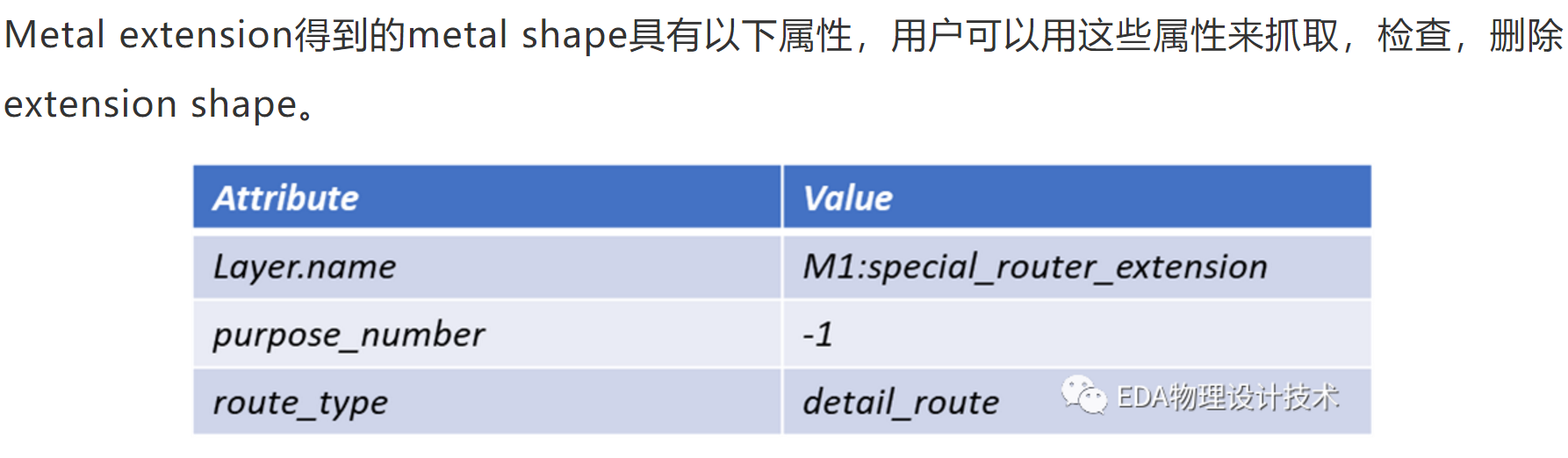

In ICC2, all related to the route command can automatically determine which metal shape minArea does not meet the requirements, and metal extension. E.g. clock_opt -from route_clock, route_auto / route_detail / route_opt / route_eco / route_group like. It is noteworthy that, M1 of PG shape. If not minArea requirements, ICC2 automatically extension.

How to Debug

After the small partners of actual use, some little friends will encounter a lot of minAreaDRC ICC2 reported discovery tools do not have the problem of metal extension. First clear is that, ICC2 will be able to correctly carry out metal extension in all cases the correct input. If not, it must be entered where there is a mistake. Here, I share with you a simple example encountered in practice metal extension error.

Extension 1. All net no Metal . First of all, we have to check if created correctly track, preferred grid on the track is correct. It is noteworthy that small tips, when third-party tools def read from, preferred grid information will be lost, therefore, need to re-create the lower track. Secondly, we have to check if created correctly routing guide. We can automatically create routing guide use the following command in accordance boundary cell: set_boundary_cell_rules -add_metal_cut_allowed

2. All PG no metal extension, and the signal wire has a metal extension. In this case we need to check whether the PG physical_status don't_touch or is_fixed?

3. Signal NET part of the cell without Extension Metal . Need to check whether the correct cell legalize, cellpin the color is correct (consistent with the track's color).

4. Part no PG Extension Metal . Check for proper set set_app_option -name route.common.disable_net_type_blockage -value false. Reasons, routing_blockage inside the standard cell net_type as: analog_signal, clock, reset, scan , signal. That routing_blockage of net_type does not include PG mesh, why PG extension is blockage of it? route.common.disable_net_type_blockage The default value is false. When the error is set to true, routing_blockage will no longer be distinguished according to whether barrier net_type certain net, but the blockage of all net. Therefore, the block lived PG extension.